Posted By: Southern Fabricating Machinery Sales | Posted On: October 26, 2020

CNC Machines for Horizontal vs Vertical Milling

There is a wide variety of milling machines available. Some are very flexible and are used for a lot of different machining operations, others are very specialized to work with certain materials or types of parts. The two machines we will look at are the Vertical and Horizontal CNC milling machines and what their applications are. Both do basically the same thing, but they are just built a bit differently.

What is a CNC Milling Machine?

The acronym CNC stands for computer numerical control which simp;ly put automates the motions and spindle of the CNC machine whether vertical or horizontal. A CNC / computerized machine can work faster and far more precisely than its predecessors the manual mill. They both work with the process of taking a piece of metal or other material and removing material to make the shape desired to the tolerance expected.

All automated motion control machines have three primary components, a command function, a drive or motion system, and a feedback system. Once programmed, it can make any type of shape with any number of hard materials.

The Basics of CNC Machines for Horizontal Milling

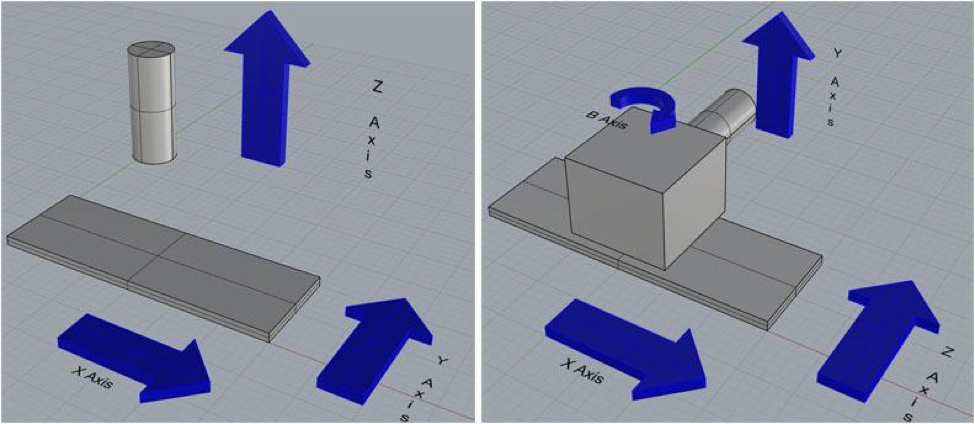

The horizontal milling machine is a type of machine tool with a spindle parallel to the worktable It is most often used to make various planes, inclined planes, and grooves with cylindrical milling cutters, disc cutters, angle cutters, forming cutters, end mills, and more.

Horizontal milling machines do not use a fixed spindle. That means multiple cutters can be mounted on a horizontal spindle across the table when the horizontal arbor stretches across the entire length of the bed.

The rotating cutting tool press against the workpiece and remove excess materials from the piece to make whatever it is programmed to. Some horizontal machines have a built-in rotary table that allows milling at different angles or to allow the machine to contour along with the rotation of the table.

Advantages of Horizontal Machining Center:

-

- 4 Sided Machining Capability

- Automation / Pallet Changer Included

- Chips Free Fall away from work area

- Higher Cutting Capabilities due to machine stiffness.

Disadvantages of a Horizontal Machining Center

-

- Cost

- Smaller Work Area

- Higher Fixturing Cost.

- Space, Generally HMC’s have larger footprints for the same work area as VMC’s offer.

The Basics of CNC Machines for Vertical Milling

Vertical Machining Centers are the more popular milling machinery used for manufacturing. They usually cost less than horizontal machining centers, which makes them a better investment for your shop but are slightly less of a production machine.

Their lower price means better revenue but also the ability to extend those saving on to the clients. It also means there will be a larger pool of trained operators to run the machines. They are easy to program and run, so they don’t eat up a lot of time for setup and spend more time producing. They are the more popular choice for simpler jobs.

Advantages of Vertical Milling:

-

- Investment cost

- Flexibility

- Accessibility to work zone

- More operators familiar with

Disadvantages of a Vertical Machining Center

-

- Additional rotary axis reduce travel space and are limited in capacity

- Machining only on 1 side per setup (w/o add’l rotary axis)

- Chips/Swarf pile up in the work zone requiring work stoppage to clean.

- Machining Capability generally less due to lower rigidity.

How To Choose The Best CNC Machines based on Your Needs

The machine you choose will depend on what you will need it for the most. If your projects are more complex, demand higher production rates, then the horizontal milling machine will be more capable to handle that. Horizontal machines are also better for working with large and very heavy material and making products that need working on multiple sides or in several planes.

Vertical machines are better for making items where you only need to process one side. They are also simpler and less complex internally because the spindle doesn’t have to be designed to move in two directions.

View SFM'S Inventory of CNC Machines for Horizontal and Vertical Milling

Please check out our inventory for all our new and used machinery. You can save a great deal of money when you buy used equipment. We are also open to trades, buying your old equipment, or help you broker them for more value right from your floor.

Contact Southern Fabricating Machinery Sales today. If we don’t have the machine you want on hand, we can find it for you. With an extensive working knowledge of manufacturing systems, going back over 30 years coupled with real hands-on shop experience, our representatives can best assist you in locating and securing the best machinery for your application.