Every day, product engineers and job shop owners are faced with a project or part that needs to be produced using steel. If it is not specified in the design, then you will need to decide whether to use hot rolled or cold rolled steel. Making the right choice will help you create the best solution for quality and cost. Let's break down the difference between hot rolled and cold rolled steel.

Every day, product engineers and job shop owners are faced with a project or part that needs to be produced using steel. If it is not specified in the design, then you will need to decide whether to use hot rolled or cold rolled steel. Making the right choice will help you create the best solution for quality and cost. Let's break down the difference between hot rolled and cold rolled steel.

About Hot Rolled Steel

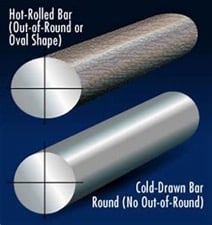

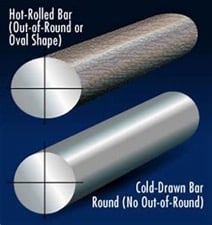

Hot rolled steel is a mill process that involves rolling the steel at very high temperatures, more than 1,700 degrees Fahrenheit, called the recrystallization stage. At these high temperatures, it is easy to shape, form, and change the cross sectional area of the steel by using compressive rolling forces.

As the steel cools, it will shrink and there will be less control over the final size and shape. This is the reason why hot rolled steel will always cost less than cold rolled steel in the same size and shape.

As the steel cools, it will shrink and there will be less control over the final size and shape. This is the reason why hot rolled steel will always cost less than cold rolled steel in the same size and shape.

Hot rolled steel is usually used when precise shapes and tolerances are not required.

There are three easy ways to identify hot rolled steel:

- A scaly and semi-rough surface finish,

- Rounded edges on square and rectangular shaped bar stock, and

- A non-oily surface.

Typical applications for hot rolled steel include:

- All types of trailer parts,

- Ornamental railing,

- Railroad tracks, and

- Construction and welding trades.

About Cold Rolled Steel

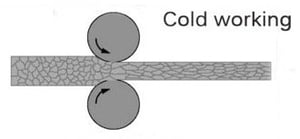

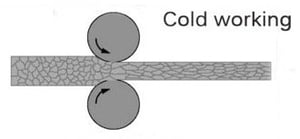

Cold rolled steel is, basically, hot rolled steel that has been processed further. The additional processes provide better finishes and closer dimensional tolerances. Other terms used for cold rolled steel include cold finishing and cold drawn steel.

This is commonly used in bar stock. In this process, the hot rolled steel is brought to room temperature and then drawn through multiple dies under pressure to reform the grain structure into smaller and more aligned grains—which makes the material stronger and much harder while creating the desired shape.

The three easy ways to identify a piece of cold rolled steel are:

- An oily or greasy finish,

- A very smooth surface, and

- Very sharp edges on square or rectangular bar stock.

Cold rolled steel is mainly used for machined parts like automotive components, manifolds, and connectors — or, whenever tighter tolerances are required.

Cold rolled steel is mainly used for machined parts like automotive components, manifolds, and connectors — or, whenever tighter tolerances are required.

When planning or quoting on a part or project, it is important to know what the end goal will be, how it will be used, and if any machining or sizing will be required. All of these factors will help you decide if hot rolled or cold rolled steel will be the best choice for your metal forming work.

Every day, product engineers and job shop owners are faced with a project or part that needs to be

Every day, product engineers and job shop owners are faced with a project or part that needs to be  As the steel cools, it will shrink and there will be less control over the final size and shape. This is the reason why hot rolled steel will always cost less than cold rolled steel in the same size and shape.

As the steel cools, it will shrink and there will be less control over the final size and shape. This is the reason why hot rolled steel will always cost less than cold rolled steel in the same size and shape.

Cold rolled steel is mainly used for machined parts like automotive components, manifolds, and connectors — or, whenever tighter tolerances are required.

Cold rolled steel is mainly used for machined parts like automotive components, manifolds, and connectors — or, whenever tighter tolerances are required.