Posted By: Southern Fabricating Machinery Sales | Posted On: March 13, 2018

A Little Bit About Swiss Turning Machines

The Swiss principal was developed in Switzerland in the 1800s for the turning of very small, intricate, and long watch parts. The watch industry has been very important to the Swiss people for a long time, so they invented the Swiss Lathe that made small parts that could not be made on a conventional “fixed headstock lathe.” This was due to the extreme length-to-diameter ratio found in many watch parts as well as the small diameters that required turning finesse with small, specialized tooling.

The Swiss principal was developed in Switzerland in the 1800s for the turning of very small, intricate, and long watch parts. The watch industry has been very important to the Swiss people for a long time, so they invented the Swiss Lathe that made small parts that could not be made on a conventional “fixed headstock lathe.” This was due to the extreme length-to-diameter ratio found in many watch parts as well as the small diameters that required turning finesse with small, specialized tooling.

Fixed Headstock Turning

The fixed headstock principal has the tendency for the part to deflect from tool pressure when the ratio of length to diameter gets beyond 4:1. That was normally the limit on a conventional lathe where the workpiece was fed out to length and then the bar was turned to a given diameter. In some cases, you could go beyond 4:1 depending on the size of the stock, the length and diameter to be turned, and the number of passes applied to complete the finish diameter.

The use of a tailstock can assist the ability of turning longer lengths, as can a steady rest, but these two features are only effective on larger parts. In diameters where Swiss machines come into play, we’re generally looking at bar sizes up to 38mm—and the largest use under 1” bar diameters.

The use of a tailstock can assist the ability of turning longer lengths, as can a steady rest, but these two features are only effective on larger parts. In diameters where Swiss machines come into play, we’re generally looking at bar sizes up to 38mm—and the largest use under 1” bar diameters.

The Swiss Automatic is called several different names such as Swiss Type, Swiss Screw Machine, Sliding Headstock Lathe, etc. Swiss Computer Numerical Control (CNC) Machines are used in several industries where nothing else would be as effective—such as medical instruments, bone screws, dental implants, electrical connector contact pins, watch parts and many other small, intricate or complex parts always made from barstock.

Swiss Automatic Lathes are designed specifically for running barstock and normally use 12' long bars. In many cases, these machines have automatic magazine bar feeders that can rack up several bars that are automatically reloaded once a bar is used up. High volume production is a common practice with CNC Swiss Machines.

It is a very rare case in which a Swiss is used for secondary operation work where a turned part is re-clamped in the main spindle to do additional work on a part.

Typical Swiss Parts

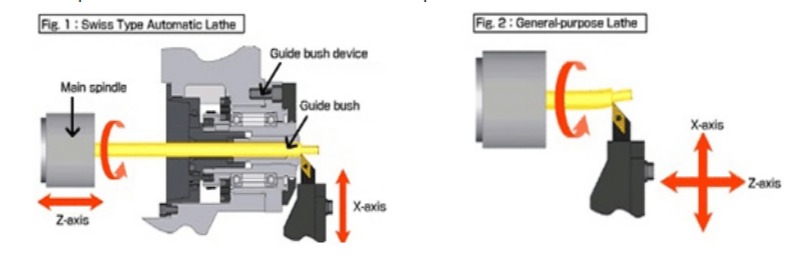

The key factor that makes the Swiss turning machine so effective for turning long, slender parts from a bar is the use of a guide bushing. The guide bushing is mounted in the headstock casting and the ID of the bushing is sized to the diameter of the bar within tenths. The bar is clamped in a collet located in the sliding headstock behind the guide bushing. The bar is pushed through the guide bushing (Z Axis) and the turning tools, located just in front of the guide bushing, move in to a given diameter (X Axis) and the turning takes place with almost zero deflection of the workpiece.

The key factor that makes the Swiss turning machine so effective for turning long, slender parts from a bar is the use of a guide bushing. The guide bushing is mounted in the headstock casting and the ID of the bushing is sized to the diameter of the bar within tenths. The bar is clamped in a collet located in the sliding headstock behind the guide bushing. The bar is pushed through the guide bushing (Z Axis) and the turning tools, located just in front of the guide bushing, move in to a given diameter (X Axis) and the turning takes place with almost zero deflection of the workpiece.

In the early days of cam-driven Swiss automatics, the guide bushing was non-rotating. So, the bar had to be centerless and ground to very close tolerance so that a close fit to the guide bushing ID remained consistent. Because the bar was rotating within a non-rotating bushing, high friction could occur; this demanded that cutting oil be directed to the guide bushing as well as the cutting tools.

Today, nearly all Swiss-style turning machine builders include a driven, synchronous guide bushing that rotates 1:1 with the headstock collet, which eliminates a lot of the tendency for friction and heat. That being said, most Swiss houses still use cutting oil as opposed to water-soluble cutting fluid. The use of cutting oil helps to keep the machine lubricated and free off rust and premature wear. Used Swiss machines lose a lot of their value when water-based coolant has been used and become very hard to resell when this information is known to a prospective buyer.

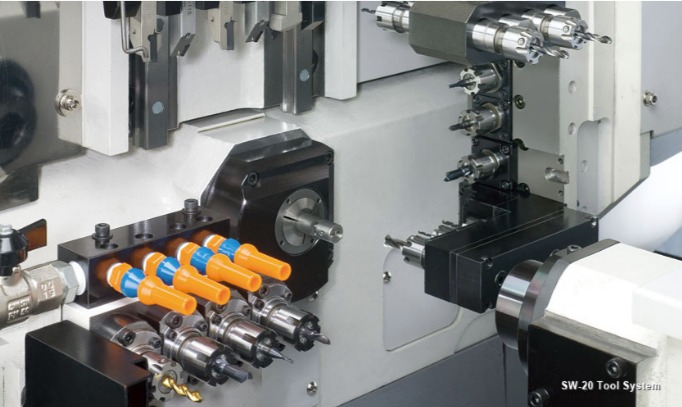

Today’s CNC Swiss Automatic machines have advanced from the original cam-driven Swiss that was strictly a turning machine. Today, nearly all Swiss machines have two spindles—main and sub—each equipped with an independent “C” Axis, live tooling for each spindle, and a “Y” Axis that allows a live tool to move above and below the centerline. Many builders also include a “B” or rotational axis for a bank of tooling able to perform complete features on a part.

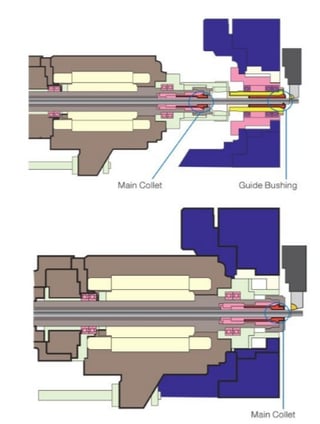

Beyond all of these modern advances in Swiss turning machines, you also can find hybrid models from several builders that offer their fully-loaded machines that can run either with or without the guide bushing. This is used when a series of parts to be run is relatively short and it becomes more practical to run the series without the guide bushing. To run without the guide bushing, the bushing holder is removed, allowing the headstock collet to protrude into the headstock casting, which enables the machine to operate like a fixed headstock lathe with a linear Z Axis. Now, the stock can be normal mill-run material with some variation in the OD.

The drawings below show the difference between a sliding headstock with the guide bushing and the same machine with the guide bushing removed so that the part can be turned directly from the headstock collet. This ability to change back and forth is only available on certain brands and models within those brands.

The drawings below show the difference between a sliding headstock with the guide bushing and the same machine with the guide bushing removed so that the part can be turned directly from the headstock collet. This ability to change back and forth is only available on certain brands and models within those brands.

Used Swiss machines are usually still in great running condition after 8-10 years of high production running. The use of cutting oil greatly extends the life of the mechanical portion of the machine—such as the linear guide rails found on most Swiss lathes. Also, the small and often delicate parts tend to not tax the machine, as would be more the case on an 8” or 10” chuck lathe.

The most popular Swiss machines are from Star, Citizen and Tsugami—but there are several others that take up a smaller share of the market (such as Tornos, Hanwha, and Nexturn). Normally, finding a top brand that is 4 or 5 years old is rare since people tend to hang onto a well-equipped Swiss until they see major changes in technology before they even consider putting the machine up for sale.