The BLM BC80 CUTTING & END-FINISHING SYSTEM is a unique machine designed to maximize productivity in end machining operations for tubing up to 3.125" (80MM) in Diameter. Combining the performance of a dual spindle turning center with the speed of a sawing operation the system can cut, face and chamfer spacers, bushings, rod and bar stock and perform that operation extremely quickly. Capable of outputting up to 2,200 parts per hour the BLM BC80 is second to no other system in its dedicated focus.

- BC80 is both the highest performing and cost-effective machine on the market designed for round the clock production of bushings up to 80 mm (3.15”) diameter and lengths from 10-350 mm (0.4” to 13.75”)

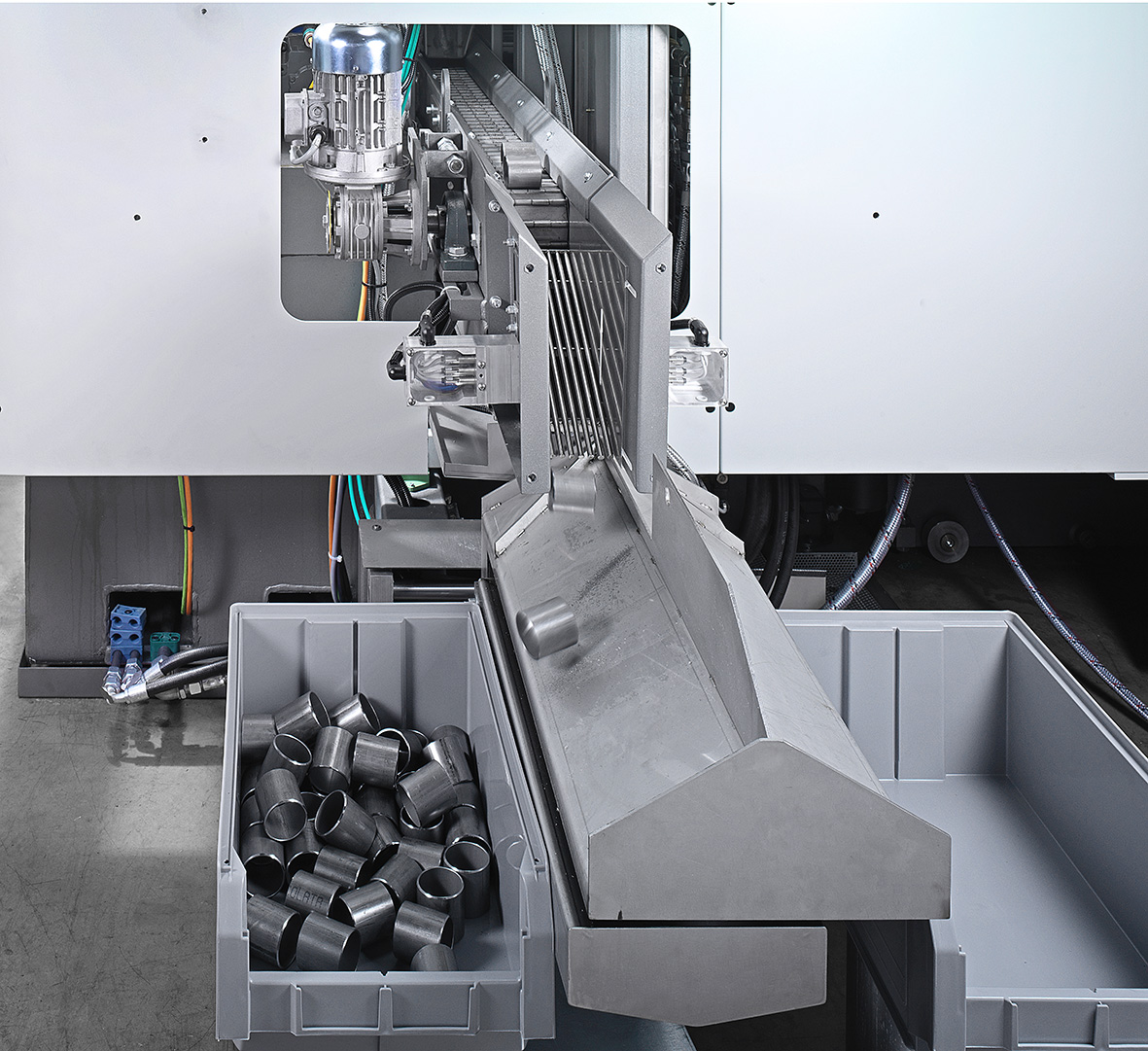

- Separate collection of end-pieces and swarf - chips and scrap drops managed separately

- Tube surface is protected from scratches

- All tube diameter changeover adjustments done from a single location

- User-friendly graphical interface

- The finished part unloader has a two-position separator that can used when changing collection bins or to segregate scrap

- Dynamic washing / flushing of the finished components

- Tool wear monitoring

- In-process part measurement and 100% part inspection including detailed reporting

Sold

.jpg)