Posted By: Southern Fabricating Machinery Sales | Posted On: February 21, 2018

Learning Used Machinery: Plate Rolls

Plate Rolls are utilized for the rolling of flat sheets of material typically steel, stainless steel or aluminum. Typical applications include the manufacture of items such as cans, tanks, pipes, pressure vessels, tanker trailers, excavator buckets and other rounded metal pieces. Plate Rolls can be either computer controlled or operated as a powered manual machine. However, even with CNC controls, material variations can require adjustments and operator finesse in order to achieve the desired results.

Plate Rolls are designed to be able to roll a variety of material thicknesses and diameters, however, there are limitations due to the physical properties of the plate roll's design. Therefore, these plate rolls are best suited for “ranges” of a user’s need. The limitations of the Plate Roll have to do with a combination of the roll's diameter (the smaller the roll the tighter the diameter that can be rolled, while the larger the roll, the less deflection is produced), the diameter being rolled and the workpiece's thickness. All rolls will pinch the material between two rolls and (by mechanical or hydraulic means) force the workpiece material into an arc. Both ends of a turning roll must be securely supported to prevent the rolls from springing apart under pressure. One end of the roll is called the “drop end” as the roll support on that end can be released either manually, hydraulically, or mechanically to remove the rolled cylinder from the top roll.

Types of Plate Rolls

2 Roll

The 2 roll style plate roll is typically used for high-volume processing of thin metals (typically 3/16” and thinner) into small diameter shapes (4”- 24” Diameter). The rolls are mounted in a vertical pattern with one roll being centered directly on top of the other. The forming roll (typically the lower of the two rolls) has a durable but flexible coating of neoprene or similar material that the upper roll pushes into creating a depression and “waves” around the point of contact. The operator feeds the workpiece into this pinched position as the rolls are turning and the deflected rubber material forces the workpiece into a rolled form around the solid roll.

Advantages:

- Very fast rolling operation.

- Easy to automate.

- No flat on rolled shape.

Disadvantages:

- Limited to thin materials.

- Limited adjustment.

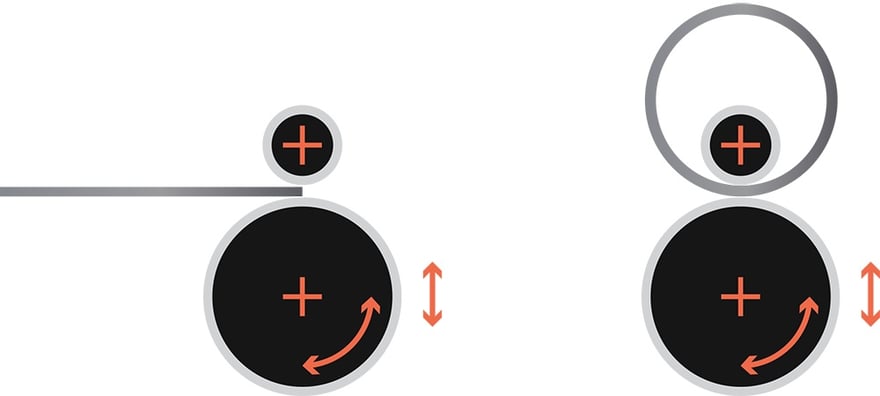

Initial Pinch

Probably the most common type of plate roll found is the Initial Pinch. This type of material roller consists of 3 rolls with 2 of the rolls mounted almost directly vertical over one another with one being a fixed roll and the other adjustable. The last roll is offset on an adjustable slide that is controlled in a motion towards the “pinch” point of the two rolls. To operate this roll, the operator inserts the workpiece material and adjusts the movable of the two vertical rolls until the workpiece is firmly “pinched” between the two rolls. Next, the offset rolls are positioned upwards towards the fixed roll forcing the workpiece to bend around the fixed roll. The rolls are then powered on and the rolling process begins with adjustment to the offset roll to reach the desired diameter.

Advantages:

- Very common roll.

- Easy to operate.

- Typically used in thin material applications (1/4” or less).

Disadvantages:

- Material must be turned around or fed all the way through the machine to “pre-bend” trailing edge of workpiece.

- Adjustments are not exact and must be checked and rechecked during rolling process.

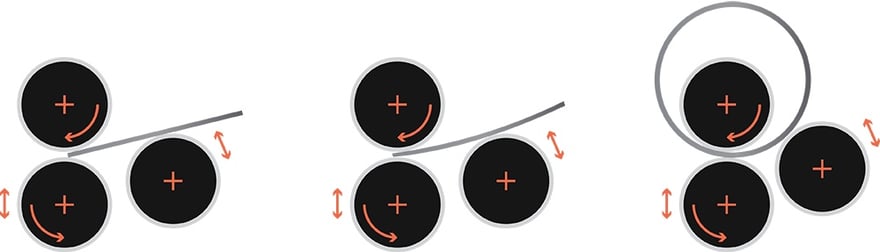

Double Pinch

This type of roll is commonly used for medium plate applications. The top roll is fixed and the bottom two rolls are movable at an angle towards the top (fixed roll) or the bottom two rolls are fixed with the top roll being movable. Material is fed in until it rests on the bottom two rolls. The rolls are then brought together with the top roll until the desired position is achieved to obtain the correct diameter; at which time the rolling process begins.

Advantages:

- Very common roll.

- Easy to operate.

- Typically used in medium material applications (1/4” – 3/4”).

Disadvantages:

- Large flats are left on the end of the material.

- Adjustments are not exact and must be checked and rechecked during rolling process.

- Material is never fully “pinched” between rolls and can slip • Material is fed in at an angle.

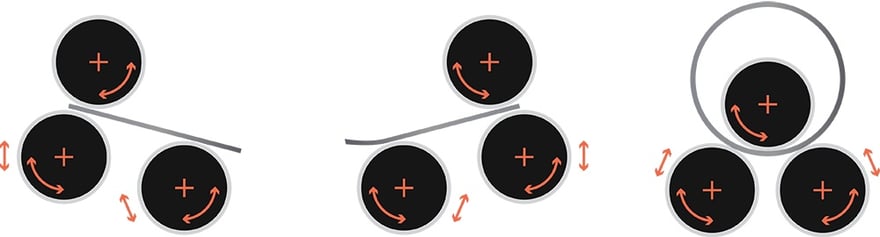

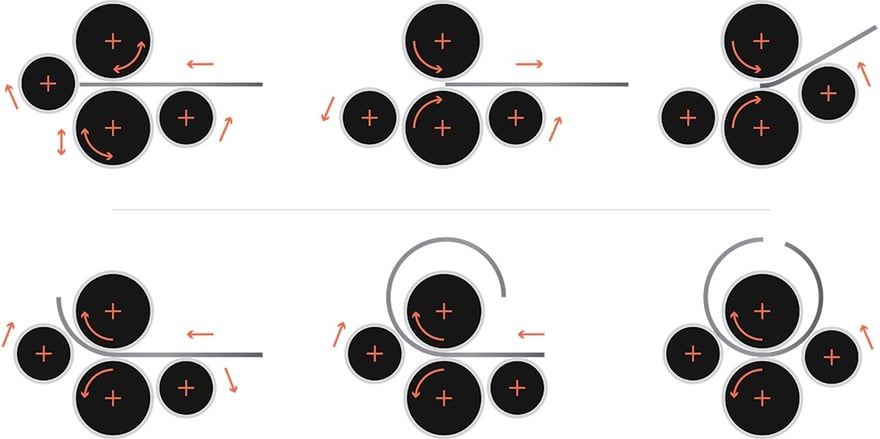

4-Roll

This type of plate roller is the only type where Computer Numerical Control of the rolls makes a great deal of sense as this is the only plate roll that can easily roll oblongs or out-of-rounds shapes. This roll has two rolls centered vertically over one another and two movable rolls positioned directly on either side of the center, or “pinch,” rolls.

These movable rolls can be positioned at an angle from well below the material to where the centerline of the positioning rolls outside diameter can almost meet the pinch point of the “pinch” rolls. In order to operate this machine, the operator first positions the “Leading” roll as a material stop or gage.

The opposite roll is positioned where the diameter of the acts like a material support assisting in loading by allowing the material to be supported across the top diameter. The pinch rolls are opened and material is inserted and squared against the “leading” roll. The pinch rolls are then pressed together and the material is slightly retracted by rolling the pinch rolls backward. The leading roll that was positioned as the material gage is then lowered to allow the leading edge of the workpiece to pass over it.

As the rolling begins, the leading roll that now forces the material up into the desired radius. Rolling continues until the trailing edge of the workpiece is close to passing the “trailing” role that was initially used as a support. The “trailing” roll now forces the trailing edge of the material up into the final position to achieve the proper diameter. If these rolls are controlled via numerical control, the “Leading” roll and the “Trailing” roll can automatically adjust position and roll oblong, egg-shaped or other non-round parts.

Advantages:

- Material is always firmly pinched.

- Flats are minimized due to adjustment of both leading and trailing rolls.

- Can be used for almost all material thickness applications.

- Material is fed into unit flat.

- Machine can save a great deal of space as material does not need to be rotated around & fed in backward to pre-bend the opposite end.

- Can roll non-round shapes.

Disadvantages:

- Price.

Whichever process you choose should be based on the minimum requirements of your part AND budget. Southern Fabricating Machinery Sales represents manufacturers and used machinery from many different processes, makes, and models to ensure we can offer you the right solution for your application. Contact us today for more information on new or used plate rolls and the process of rolling steel.

To download a PDF version of this information, please click here.