For many years we as manufacturers, distributors and OEM’s of laser cutting systems were taught that Power (KW) IS Capacity & Speed. We had the data to prove that increasing your wattage on a machine increased your speed and thus throughput. While all of this was true, it only applied to the CO2 technology of the time. Unfortunately OEM’s and Dealers were slow to educate equipment buyers/Manufacturer's of the differences in cutting speeds & capacities that Solid State and Fiber Lasers brought to the table.

& Speed. We had the data to prove that increasing your wattage on a machine increased your speed and thus throughput. While all of this was true, it only applied to the CO2 technology of the time. Unfortunately OEM’s and Dealers were slow to educate equipment buyers/Manufacturer's of the differences in cutting speeds & capacities that Solid State and Fiber Lasers brought to the table.

As the argument did not go away with the introduction of this new technology, the dealers capitalized on the need for more power as higher power and wattages also meant more sales dollars. But the reality was that there was much learning that needed to be done for OEM’s, Dealers and Manufacturers alike. Fiber Lasers were simply different than their cousin, the CO2 laser resonator. They operated much more efficiently, lost far less power from mirrors and lenses then their CO2 counterparts thus put more cutting power to the torch. They are more capable and able to focus the beam into 1/10th the diameter of a CO2 system giving lower wattage systems much more capability and power.

%20NEW%20Polaris%20L510%20Fiber%20Laser%20Cutting%20System%20-%20Pic%2018.jpg?width=343&name=(2025)%20NEW%20Polaris%20L510%20Fiber%20Laser%20Cutting%20System%20-%20Pic%2018.jpg) Technically speaking Fiber lasers have a different emission wavelength of around 1.07 µm, compared to traditional CO2 lasers that emit the beam at 10.6 µm. This means that the 1.07 µm laser light is reflected less, absorbed more easily, and the shorter wavelength can be focused into a spot that is around 1/10th of the diameter of a comparable CO2 beam. This provides a dramatically higher power density, making metal cutting easier. In layman's terms this simply means you can do much more with less power from a Solid State based Fiber Laser System then that of traditional CO2's.

Technically speaking Fiber lasers have a different emission wavelength of around 1.07 µm, compared to traditional CO2 lasers that emit the beam at 10.6 µm. This means that the 1.07 µm laser light is reflected less, absorbed more easily, and the shorter wavelength can be focused into a spot that is around 1/10th of the diameter of a comparable CO2 beam. This provides a dramatically higher power density, making metal cutting easier. In layman's terms this simply means you can do much more with less power from a Solid State based Fiber Laser System then that of traditional CO2's.

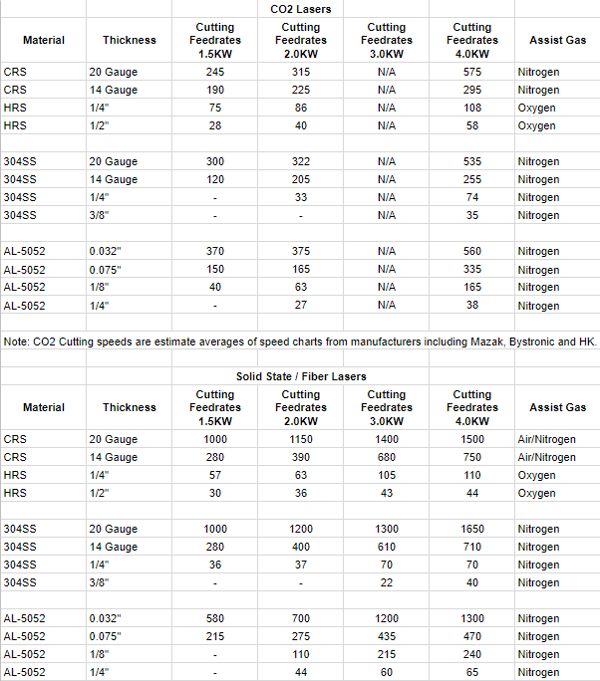

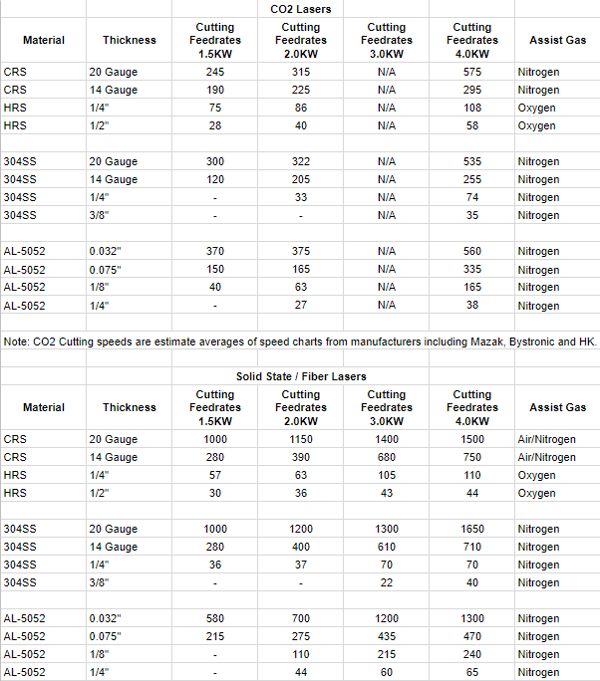

The real world comparisons or, 'Where the Rubber Meets the Road' of Fiber vs CO2 technology is in the cutting speeds and capacities. It’s here that the arguments for, or against, more power become reality. You will see in the chart below that in Solid State Fiber Cutting increasing power over 2KW generates slightly more speed, but not significantly, which is opposite of what we see with CO2 technology. What adding KW power does do in fiber is increase the Cutting Thickness capacity as the chart below demonstrates.

What we see in the above chart is only a small advantage moving from 2KW to 3KW and even less of a difference adding the additional 1KW of a 4KW system. The cutting charts tell us that in general, the 2-3KW systems are more than capable for a wide variety of processes and applications and can save a buyer tens of thousands, or hundreds of thousands of dollars over higher powered systems. Further with the use of Solid State Fiber Lasers the capabilities to cut other materials such as Brass and Copper add to the systems and your shops capability.

What we see in the above chart is only a small advantage moving from 2KW to 3KW and even less of a difference adding the additional 1KW of a 4KW system. The cutting charts tell us that in general, the 2-3KW systems are more than capable for a wide variety of processes and applications and can save a buyer tens of thousands, or hundreds of thousands of dollars over higher powered systems. Further with the use of Solid State Fiber Lasers the capabilities to cut other materials such as Brass and Copper add to the systems and your shops capability.

At Southern Fabricating Machinery Sales, Inc. we know Lasers and whether your in the market for a new or used system, fiber or CO2 we have the knowledge and systems available to help you make the right choice for your Needs AND Budget. Give us a call today at 813-444-4555, email us at sales@southernfabsales.com or browse our website at www.southernfabsales.com for more great information on machines and machining technologies.

Click HERE to read more articles about Laser Cutting

Click HERE See our available Laser Systems

& Speed. We had the data to prove that increasing your wattage on a machine increased your speed and thus throughput. While all of this was true, it only applied to the CO2 technology of the time. Unfortunately OEM’s and Dealers were slow to educate equipment buyers/Manufacturer's of the differences in cutting speeds & capacities that Solid State and Fiber Lasers brought to the table.

& Speed. We had the data to prove that increasing your wattage on a machine increased your speed and thus throughput. While all of this was true, it only applied to the CO2 technology of the time. Unfortunately OEM’s and Dealers were slow to educate equipment buyers/Manufacturer's of the differences in cutting speeds & capacities that Solid State and Fiber Lasers brought to the table.%20NEW%20Polaris%20L510%20Fiber%20Laser%20Cutting%20System%20-%20Pic%2018.jpg?width=343&name=(2025)%20NEW%20Polaris%20L510%20Fiber%20Laser%20Cutting%20System%20-%20Pic%2018.jpg) Technically speaking Fiber lasers have a different emission wavelength of around 1.07 µm, compared to traditional CO2 lasers that emit the beam at 10.6 µm. This means that the 1.07 µm laser light is reflected less, absorbed more easily, and the shorter wavelength can be focused into a spot that is around 1/10th of the diameter of a comparable CO2 beam. This provides a dramatically higher power density, making metal cutting easier. In layman's terms this simply means you can do much more with less power from a Solid State based Fiber Laser System then that of traditional CO2's.

Technically speaking Fiber lasers have a different emission wavelength of around 1.07 µm, compared to traditional CO2 lasers that emit the beam at 10.6 µm. This means that the 1.07 µm laser light is reflected less, absorbed more easily, and the shorter wavelength can be focused into a spot that is around 1/10th of the diameter of a comparable CO2 beam. This provides a dramatically higher power density, making metal cutting easier. In layman's terms this simply means you can do much more with less power from a Solid State based Fiber Laser System then that of traditional CO2's. What we see in the above chart is only a small advantage moving from 2KW to 3KW and even less of a difference adding the additional 1KW of a 4KW system. The cutting charts tell us that in general, the 2-3KW systems are more than capable for a wide variety of processes and applications and can save a buyer tens of thousands, or hundreds of thousands of dollars over higher powered systems. Further with the use of Solid State Fiber Lasers the capabilities to cut other materials such as Brass and Copper add to the systems and your shops capability.

What we see in the above chart is only a small advantage moving from 2KW to 3KW and even less of a difference adding the additional 1KW of a 4KW system. The cutting charts tell us that in general, the 2-3KW systems are more than capable for a wide variety of processes and applications and can save a buyer tens of thousands, or hundreds of thousands of dollars over higher powered systems. Further with the use of Solid State Fiber Lasers the capabilities to cut other materials such as Brass and Copper add to the systems and your shops capability.