Having been a manufacturer of waterjets I am very aware of the importance of good quality water BUT more so I also am aware of the significant trade-off of the investment in the initial system, and more importantly the daily investment in the operating costs it takes to make good quality, or "polished water." In most cases (90% of the time) tap water is sufficient (see link HERE) to provide good seal life without any additional treatment (although a sediment filter is recommended). The addition of a simple water softener system can add significantly to the hours of seal life. This is recommended as the next water treatment step NOT a closed loop system. The addition of the "end-all (last resort) closed loop water recycling and polishing system (as pictured below) can extend your seal life to double or even triple that of normal tap water hours saving you a few hundred dollars on consumables every year. So seemingly the addition of a closed loop filtration system would be good right?

Well, yes until you start to realize the costs...

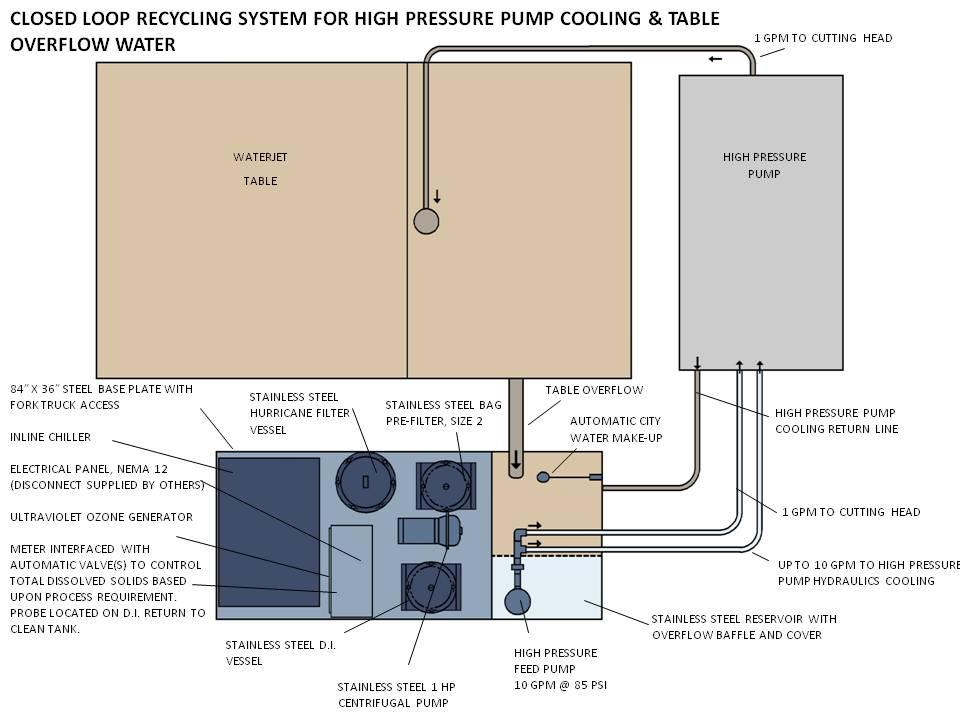

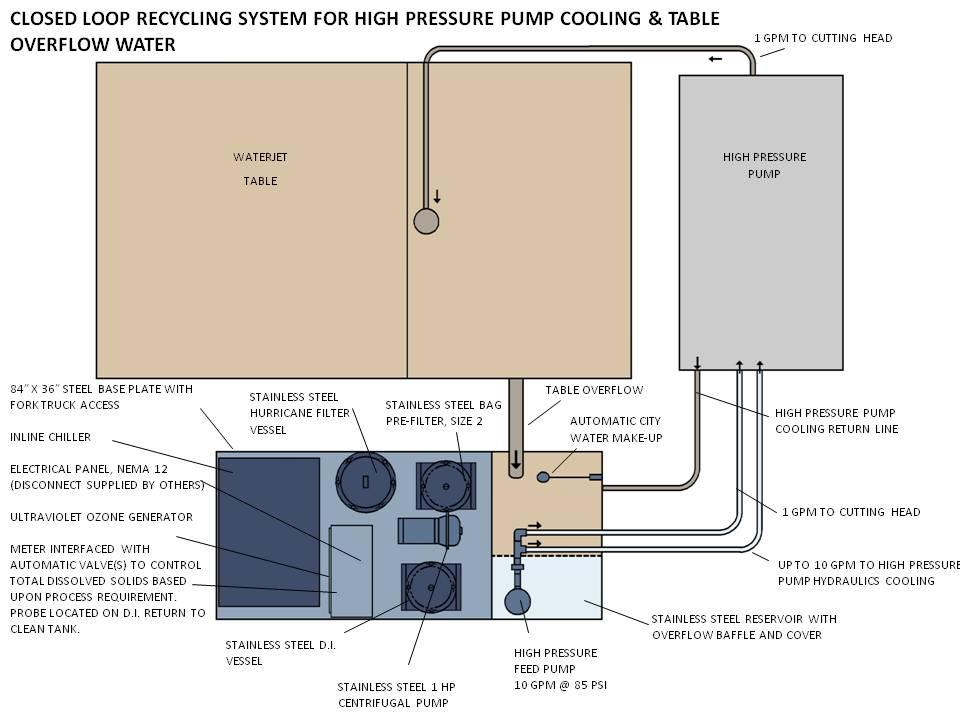

In the above pictured system is a diagram of a water treatment system for waterjets. These systems typically run about $7-9 per hour to operate.

Maintenance & Spares Required

They require maintenance such as:

- Replacing the pre-filter

- Replacing The main filter

- Cleaning out daily of the overflow baffles

- Replacing of the DI bag

- Pump Maintenance

- Chiller Maintenance

- etc...

Now also note that once you have added this system into your waterjet machine, your machine is dependent on it feeding the pressurized filtered water. Should it be down for maintenance, which is often (1-2x daily in heavy cutting), so is your machine. Also add in the increased floor space required for the system, its piping and the maintenance space required

around it. Therefore even if you WANTED to buy a system to add to your new waterjet, I would not recommend it, rather I would recommend the following action, again based on experience NOT sales hyperbole.

Try This First

- AT INSTALL: Add in-line sediment filter (such as the kind purchased for whole home use from

your local hardware store

- AFTER FIRST FEW MONTHS: After replacing first set of pump seals measure hours of high

pressure pump usage until next seal change is required.

- Under 200 hours means you probably should address any water quality issue. (Move to step 3)

- 200-400 hours means you are at a good spot with your water quality being average. (Don’t waste your money on expensive filtration systems.)

- 500+ Hours of seal life and you’re rated in the excellent category of seal life. (Definitely don't waste your money)

- OPTIONAL AFTER FIRST FEW MONTHS: Add in a typical home or light industrial water softening system capable of meeting your pumps (30HP = .6 GPM, 50HP = 1.5PM) output. (repeat step 2).

In the end, closed loop water filtration systems are necessary in roughly only 20-30% of the waterjet users shops in North America due to their lack of access to a drain or extreme water contamination or usage restrictions. Remember too that a closed loop system can be added at anytime in the life of the machine at no additional costs (tapping into the feeder water lines is all that is required) so a wait-and-see approach is best. Also note that if needed you may purchase one of the many used systems available from shops that have found them to be more of an expense and maintenance headache then they are worth. Closed loop systems do not save money, they cost money, and therefore should only be employed where and when absolutely necessary.

At Southern Fabricating Machinery Sales, Inc. we are waterjet experts we know the machines, the parts and the process to make your waterjet operation successful. Call us today at 813-444-4555 to get waterjet help or visit us at www.southernfabsales.com to shop for your next waterjet cutting system.