The BLM TUBE-FORM 10 TON CNC TUBE END FORMING SYSTEM is a configurable tube end forming system with up to seven working stations. The TUBE-FORM can be outfitted with ram stations or rotary tools and rollers for tapering, flaring, threading, rolling, closing, facing, cutting and more. By combining these technologies, you can obtain formed ends with repeatability, finish and quality comparable to that obtained by turning machines. With the TUBE-FORM forming machine you can also benefit from automatic consecutive head-tail processing on both ends of a tube.

Choose your machine setup

Choose the most suitable configuration for your job.

Six ram stations

Six ram stations + One rotary tool

Six ram stations + One rolling tool

Four ram stations + One rotary tool

Four ram stations + One rolling tool

Four ram stations + Two rotary tools

Four ram stations + One rotary tool + One rolling tool

You can also trim on the machine

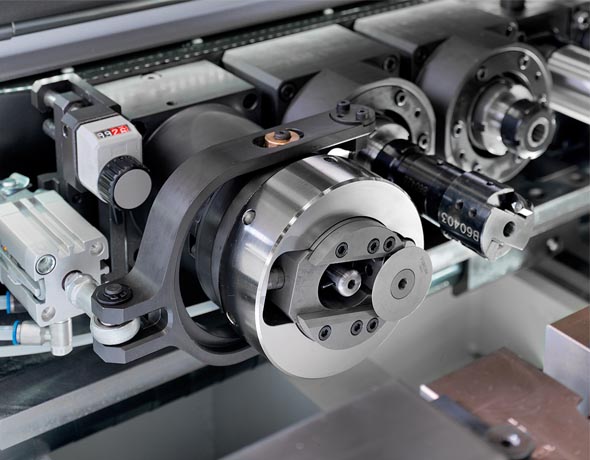

By fitting an orbital cutting device on the TUBE-FORM, you can avoid the difficult task of orienting a bent part in a secondary operation to make an accurate cut off.

An integrated cut off is a feature you will appreciate day after day.

All electric, much easier

Accuracy and repeatability of shaping operations

Complex profiles with maximum accuracy and repeatability and very quick production changeovers are possible when using the combination of "All-Electric" technology and a rotary rolling unit.

Easy to learn. Very easy to use

All possible machine parameters are programmed and managed via the CNC. This avoids the need for manual tuning adjustments thus providing considerable cycle time saving, better quality and job repeatability.

Unlimited applications