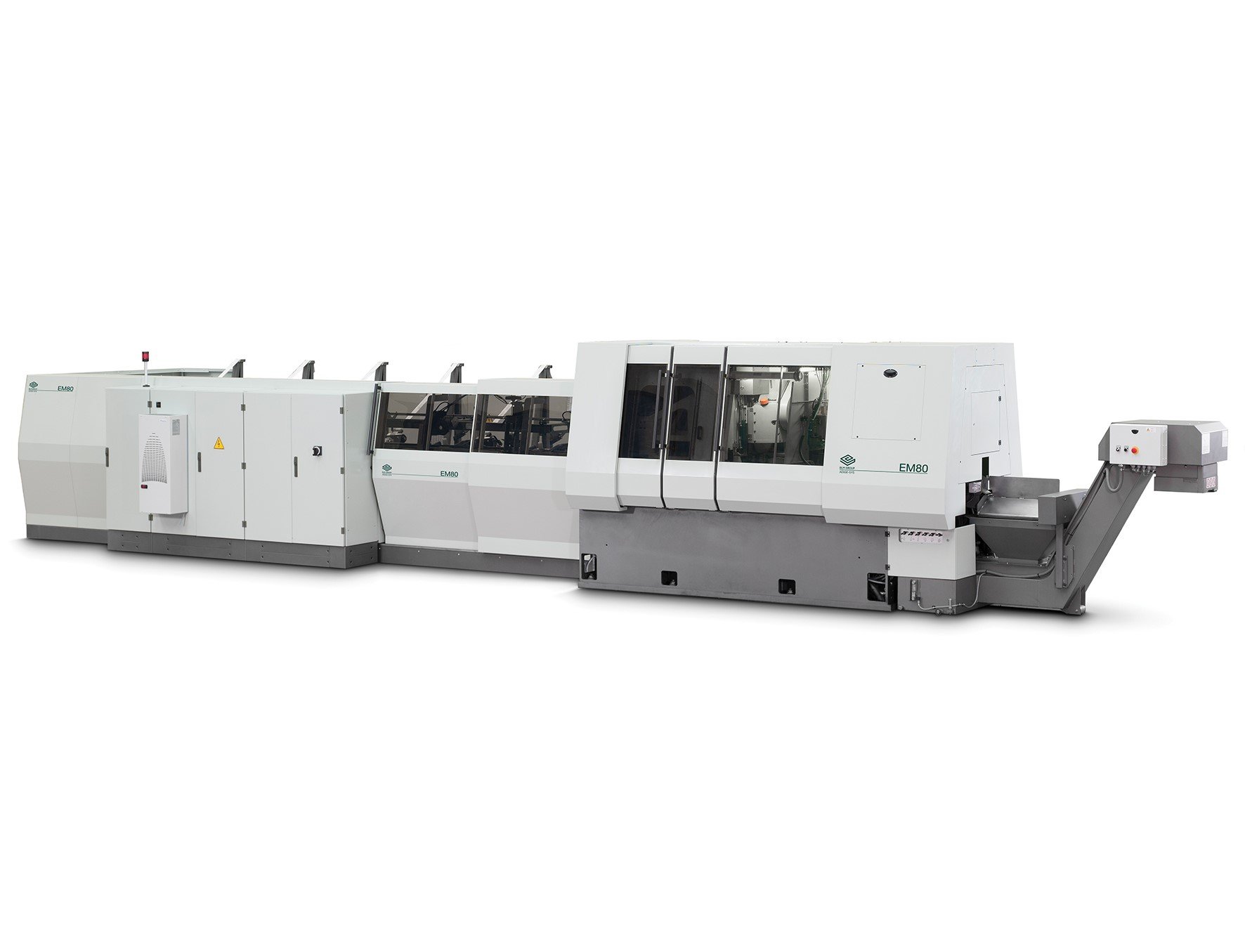

The BLM EM80 END-MACHINING SYSTEM is an integrated solution for cutting and machining operations on tube or bar ends up to 3.14" (80MM). This combination of a SAW and MACHINING CENTER provides the flexibility of a turning center with the productivity of a rotary transfer machine. Capable of finished lengths from 0.4" to 23.6" When Tube or Bar End work is what you need the BLM EM80 END-MACHINING SYSTEM cannot be beat.

- Combination saw and machining center for tubes and bar stock, which combines the flexibility of a lathe with the productivity and robustness of a transfer machine

- Parts are indexed on a three-position rotary transfer

- Inside/outside chamfering or facing

- Threading, tapping, rolling, knurling

- Longitudinal drilling, reaming, boring

- CNC machine complex turning profiles; - cross drilling and/or milling

- Optional bundle loader comes in 6.5m, 8.5m, or 12m lengths

- Optional Finished Parts Conveyor discharges parts to a two-position exit chute

- Finished Parts Bin can be emptied without machine interruption

- Scrap Conveyance System manages scrap without machine interruption

- Tool Monitoring System ensures tool integrity, process efficiency, and quality of finished parts

Sold