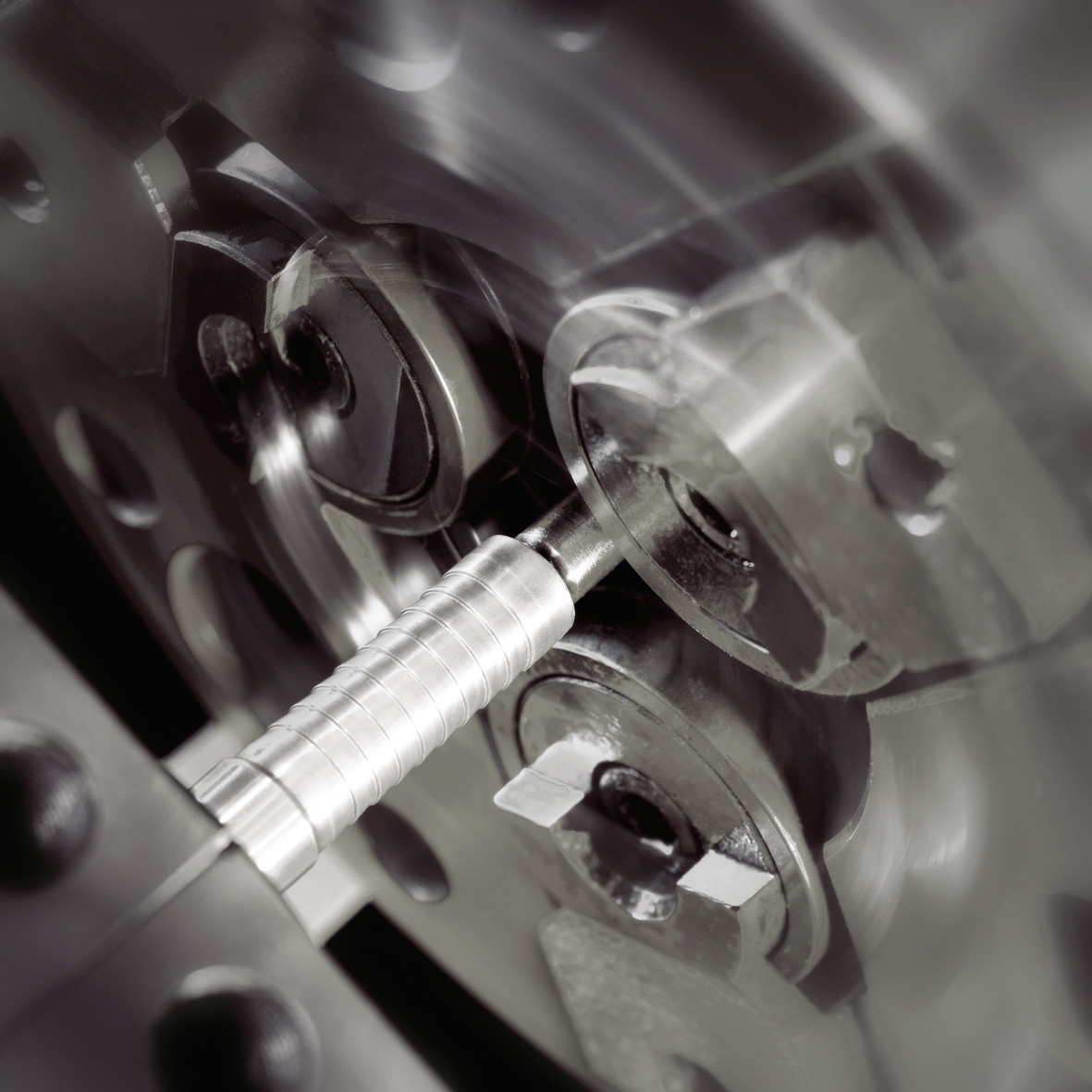

The BLM AST80 CNC TUBE END FORMING SYSTEM is set up with six processing stations: they can be outfitted with ram stations or rotary stations for tapering, flaring, threading, rolling, closing, facing, cutting and more. Combining these technologies means being able to obtain formed and finished parts with quality equal to components with machining operations. With the AST you can also benefit from automatic consecutive head-tail operations to process both ends of the tube.

FEATURES:

- Up to 6 ram stations

- Up to 6 rotary stations

- With rolling tool

- 12 Tons of Force (Up to 22 tons of force available)

- With full CNC Controls and repeatability.

- Electric-hydraulic

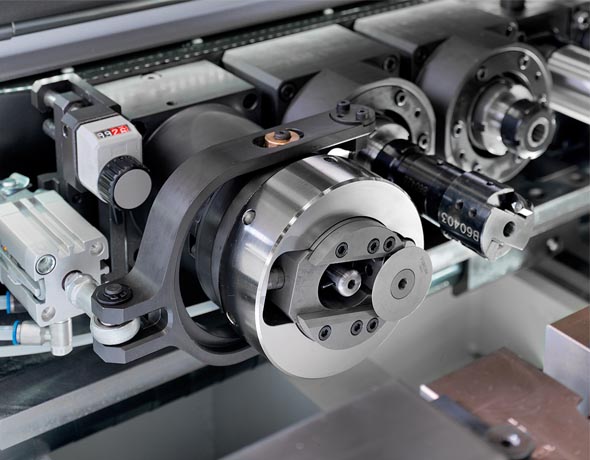

Tube trimming directly on the machine

By fitting an orbital cutting device on the AST, you can eliminate a secondary cut off operation that would typically require special fixturing to position a bent part for forming. That is a feature you will appreciate day after day.

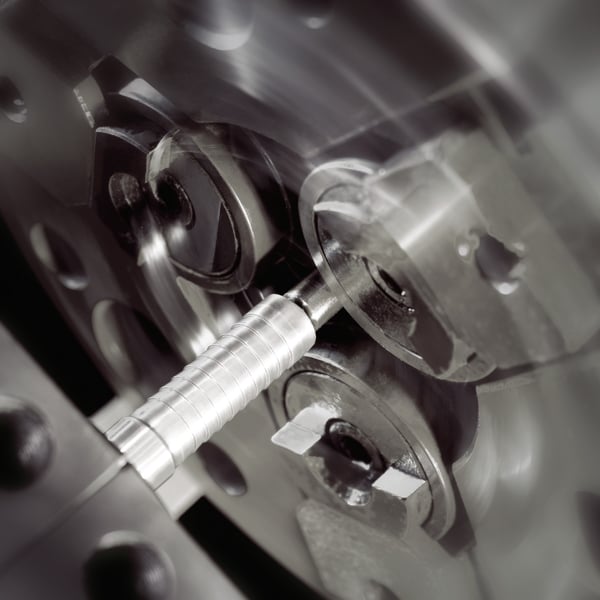

All the rolling power

You can create everything you imagine: rolling, closing, facing cutting and more, always repeatable and with finish and quality results equal to those obtained by machining operations.