Posted By: Andy Kamashian | Posted On: July 1, 2019

What Is Swiss Machining And Where Did It Come From?

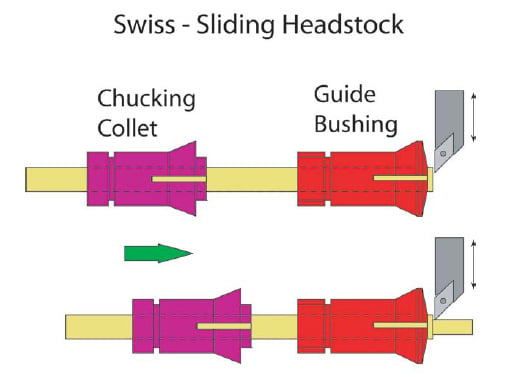

A Swiss Turning Machine, also called a Swiss Style Lathe or "Swiss Type" machine is a type of turning machine (lathe) capable of producing high production rates in small parts (1.25” diameter and under). They are especially effective in parts that are long and thin given the unique design allowing for the tooling to perform machining operations in a very close proximity to the supporting collet/guide bushing. Coupled with other unique attachments such as thread whirling many highly accurate, mass produced small parts can be produced easily. But where did “Swiss Style Machining” come from?

Swiss Origins

If you guessed it was invented in Switzerland, you’re right. Back in the 1800s machinery was going through radical changes as nothing was seemingly impossible. Watchmakers in Switzerland were making smaller and smaller components to make their products more portable (i.e. pocket watches to wristwatches) and the machinery available simply didn’t provide enough support to machine tiny diameters accurately without flexing and thus ruining the part being turned. They needed a solution that would allow for very small parts to be machined while being supported during the entire machining process.

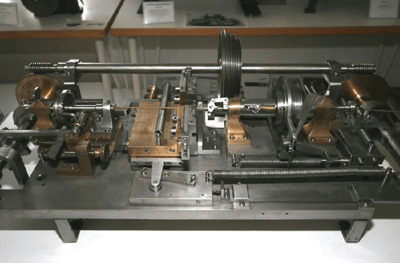

In Bien, Switzerland a watchmaker, Jakob Schweizer, had the novel idea of sliding the part along the longitudinal axis of the lathe instead of moving the tool post down the part as traditional lathes do. Further he envisioned the part would be supported in a powered turning headstock that moved the part through a guiding bushing thus keeping it fully supported during the machining process. With this new design turning tools could then perform their necessary machining operations in very close proximity to the supporting collet which provided the rigidity needed. This ingenious take on the traditional turning lathe was originally known as “Plate Machines” (referring to the original design of all the components being assembled on a steel or cast iron “plate”) adopting the “Swiss” moniker when the process was taken outside Switzerland.

By the mid 1880’s these machines were being mass produced by Nicolas Junker of Junker & Cie out of Moutier Switzerland which was, and remains, the watch making capital of the world. Later versions incorporated cams to automate the motion process for repeated manufacturing (after all they were watchmakers).Today this company is part of Tornos SA a premier manufacturer of sliding headstock machinery and although the designs have changed over the years and CNC controllers incorporated in their use the core principle of a sliding headstock has not.

Design

Today's machines still incorporate the basic principles of the “Plate” machine, i.e. the sliding headstock, but the cam positioning systems have been replaced with CNC controllers and are today much faster, better tooled and more efficient. These machines excel in making complex small parts with many features including milling, drilling, and threading possible. In the following photos you can see a 10MM Tornos Deco 2000 machine and the following photo shows the work area with the part extending from the guide bushing.

%201999%20Tornos%20Deco%202000%20Swiss%20Turning%20Center%20-%20Pic%201-1.jpg?width=500&name=(3142)%201999%20Tornos%20Deco%202000%20Swiss%20Turning%20Center%20-%20Pic%201-1.jpg)

%201999%20Tornos%20Deco%202000%20Swiss%20Turning%20Center%20-%20Pic%2014_picmonkeyed.jpg?width=600&name=(3142)%201999%20Tornos%20Deco%202000%20Swiss%20Turning%20Center%20-%20Pic%2014_picmonkeyed.jpg)

Market

Although "Swiss Screw Machines are not limited to watchmakers any more they are still widely used in that industry. Another industry that greatly uses this technology is the medical industry where surgical screws and tools are made to highly exacting standards however the technology is not limited there either. A short list of industries that employ Swiss style machining include:

- Aerospace Industry

- Watch Industry

- Medical Surgical Tools & Devices

- Computer and Connectors

- Fuel Systems

- Defense Systems

Below is a photo of many common parts made on a Swiss Screw Machine, pay particularly close attention to the non-round features that these machines are capable of producing.

Materials

Material types vary on a swiss style machine and like many other machining processes they can handle the common to extreme alloys. All of the following materials are well within the capabilities of a swiss turning machine.

- Aluminum

- Brass

- Carbon Steel

- Copper

- Exotics

- Monel

- Nickel

- Nylon

- Plastics

- Stainless Steels

- Titanium

One of the key benefits of Swiss Style Machining is the ability to machine smaller, longer and more complex parts. In other forms of machining, the tool approaches the open turning part whereas in Swiss Machining the part is guided and supported to the tool which allows for excellent accuracy for longer, thinner components and small parts however complex. The unique design also allows for the ability to perform simultaneous turning and milling as the workpiece moves instead the tool. Not only can both turning and milling operations be performed on the Swiss machine, the commonly can be performed simultaneously allowing for incredible efficiency and throughput.

At Southern Fabricating Machinery Sales, Inc. we are experts in Swiss Style Turning machinery and look forward to discussing your application and needs. Call us today at 813-444-4555 or visit us on the web at www.southernfabsales.com