Posted By: Andy Kamashian | Posted On: February 1, 2019

4 Easy Steps in Selecting the Right Horizontal Bandsaw

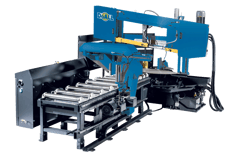

In metal cutting and fabrication shops around the country we take one if the simplest tools for granted;The Bandsaw. While it’s one of the first machines added to a fabricator’s shop, it also can be one of the best or frustrating assets a shop can have. Selecting the right saw, right from the start, is a critical step to ensure your future success. We have put together this helpful guide to with a little assistance from our friends at Do-All Saws to assist you in making the right choice when choosing your new or used band sawing system.

The 4 Critical questions you need to know when looking for a horizontal bandsaw are:

-

Will you need to cut Miter or Straight cuts only?

-

Do you need to Bundle-Cut material

-

Do you need Automatic, Semi-Auto or Manual Operation

-

Will you be using the Saw heavily (Extreme) or just a few hours a week (Intermittent Duty)?

Miter Cutting

Miter Cutting is cutting the material at any angle other than a 90°. Certain saws can adapt for these angles in a variety of ways. Some simply swing the pivoting base of the saw while other pivot the vise holding the workpiece. Others Pivot the whole body of the saw around the clamped material. Moving to the required angle can be a simple manual operation or can be a programmable operation in automatic and larger sawing systems.

Bundle Cutting

Typically found on automatic sawing systems bundle cutting can make short work of a large quantity of sawing needs. Material such as bar stock, angles, pipe, tube aetc all arrive in pre-bound bundles from the steel supplier and sawx equipped with this feature can process them all together without the need to seperate and process one piece at a time. Saws equipped for bundle cutting provide overhead hydraulic clamping on both the shuttle vise and the static vise.

Automatic, Semi-Automatic or Manual

Manual - Manual saw operation is the simplest form of a saw whereas starting the clamping the material, starting the saw blade and feeding the blade down all require the operator to initiate. While there may be hydraulic assistance on the machine (i.e. Feeds, Clamping and Blade Return to Raised Position) the saw still requires manual intervention to initiate the process.

Semi-Auto - Semi-Automatic operation handles a large portion of the tasks automatically like clamping the material,  beginning the saw blade and initiating the downstroke as well as possibly returning the blade to a raised position, however the cycle must all be initiated manually one cut at a time.

beginning the saw blade and initiating the downstroke as well as possibly returning the blade to a raised position, however the cycle must all be initiated manually one cut at a time.

Automatic - Automatic operation is the entire cycle of sawing multiple pieces from start to finish with the only operator  intervention needed is to load material and initiate the programmed sequence. These saws can be programmed to cut multiple cuts of the same length or of varying lengths (sometimes referred to as “kits” of parts) and also may be able to program varying miter angles as well. These saws are most adept for production needs and typically are outfitted with a wide range of sensors such as end of stock and blade breakage detection.

intervention needed is to load material and initiate the programmed sequence. These saws can be programmed to cut multiple cuts of the same length or of varying lengths (sometimes referred to as “kits” of parts) and also may be able to program varying miter angles as well. These saws are most adept for production needs and typically are outfitted with a wide range of sensors such as end of stock and blade breakage detection.

Duty Rating - Extreme or Intermittent Duty Rating

An extreme duty saw is likely to run 6 or more hours per shift. In cases of extreme duty usage a heavy-duty sawing system with a wide band blade and more horsepower is recommended as these systems can provide greater productivity and reliability with the overall demands of production and constant usage.

Other Factors to Consider when Selecting a Saw:

-

Design Capacity vs. Effective Capacity: A saw is most effective in materials from 1/3 to 2/3 of the rated size capacity. Using a 12″ capacity saw is not ideal for cutting 12″ solids all day.

-

Exotic Materials vs. Mild Materials: Hard-to-cut materials, like Inconel® and 316 stainless, are best cut with high production, heavy-duty machines and wide blades.

-

Your Budget vs.The Right Machine: - Purchasing a less expensive machine may fall within your budgetary constraints, but not selecting the right machine may cost you in lost production, higher maintenance and in the end, a more frustrating experience. Make sure you take the time to learn what the right system is for your needs before constraining your purchase to a predetermined budget

At Southern Fabricating Machinery Sales we are experts in saws, sawing applications and sawing systems. We can help you select the right sawing system for your needs AND budget. Call us today at 813-444-4555, visit us on the web at www.southernfabsales.com or email us your application requirements to sales@southernfabsales.com for a personal analysis and in-depth help with your sawing needs.

Click HERE to view our available sawing systems

Click HERE to download the DoAll Saws product family catalogue